800A Nitrogen Plasma Cutting Machine

Big power CNC plasma cutting machine with auto gas control function. Providing both dry and water injection plasma cutting function. Best choice for CNC stainless steel cutting application. Providing a pure N2 water injection function in order to minimize the operating cost.

- Description

- Specification

- Additional Info

- The most powerful N2 (Nitrogen) plasma cutting machine in the plasma cutting machine industry. Technology cooperation with a leading Japanese company. The maximum cutting current is unmatched at 900Amp. Deliver excellent cutting speed and cutting capacity.

- Full digital control: Plasma system is microprocessor program-controlled with a user-friendly 7" color touch panel interface. Both plasma and AVC parameters can be set up through this panel.

- Automatic gas control: Only provide the connection to the proper gas supply to the gas console. Select the cutting current, the machine will load the default value of the gas setting. The operator can decide either to apply the default value or adjust to the desired value. The machine will automatically adjust to keep the consistent output gas value in order to achieve a stable cutting performance.

- Special design for stainless steel cutting application. The plasma system can cut at higher cutting voltages, which provides larger energy to obtain higher cutting capacity.

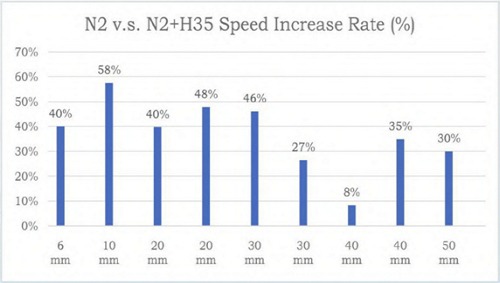

- High-speed pure N2 water injection plasma cutting: Compared to traditional Ar + H35 water injection cutting mode, the pure N2 plasma can deliver a maximum 58% higher speed. The cutting kerf can reduce maximum of 15.4%. The cutting performance is much improved.

- Super economic gas cost: Only apply N2 (Nitrogen) as plasma gas and H2O for shield gas, does not need other costly gases, like Argon (Ar) or H35 (35% H2 and 65% Argon) mix-gas to obtain an excellent cutting quality and performance in stainless steel cutting. The running cost is much reduced. (In water injection plasma cutting mode, N2 gas consumption is 29L/min @ 120Amp; 45L/min @600Amp)

- Provide both water injection and dry plasma functions. Only need to change the consumables of the torch and set up the parameters on the touch panel.

- Multi-gas functions, fit different needs.

• Pure N2 water injection plasma: Higher cutting speed and less cutting kerf compared to mixed gas. No costly gases are required, delivering economic cutting costs. The cutting surface is closer to the original stainless steel color and has less hardness zone effect against dry cutting. H2O shield during cutting, the dust is significantly reduced.

• N2 + H35 dry plasma: Provide the maximum cutting capacity. It’s the ideal feature for a thicker stainless steel cutting application.

- All new generation plasma interface: Simply select the cutting current, and the machine will automatically load the default value. With this feature, the machine does not require a very expert operator to do the job.

- The operator can also manually adjust the value, such as gas and AVC on the panel for special needs.

- In case of trouble, the machine will display the error message directly on the panel. The operator can easily check the status.

- Standard CNC: Comes with a standard CNC interface, can simply cooperate with a CNC cutting machine.

- Compared to laser cutting, plasma cutting delivers many times for cutting capacity and more economic equipment and maintenance costs.

- Heavy Duty Cycle Design: Power supply unit can work at 100% full power output (@40°C, up to 4Hr). Ideal for thicker and larger shape cutting applications. The machine is able to complete most of the continuous cutting line with one start. Avoid the tripping issue that affects the cutting surface due to the insufficient duty cycle.

- Marking Function available: The machine is able to perform plasma marking with cutting consumables. Simply change the gas setting parameter by pressing the touch panel; no need to change the consumables.

• Pure N2 water injection plasma: Higher cutting speed and less cutting kerf compared to mixed gas. No costly gases are required, delivering economic cutting costs. The cutting surface is closer to the original stainless steel color and has less hardness zone effect against dry cutting. H2O shield during cutting, the dust is significantly reduced.

• N2 + H35 dry plasma: Provide the maximum cutting capacity. It’s the ideal feature for a thicker stainless steel cutting application.

-htjmf0.jpg)

Remark:

- Turbo-Cut 800D consists of one 300A and one 600A power supply unit in parallel connection.

- Customized specifications can be made by request.

- Our products are manufactured according to the latest technology.

- We reserve all rights for product improvement. Photo(s) are for reference only.

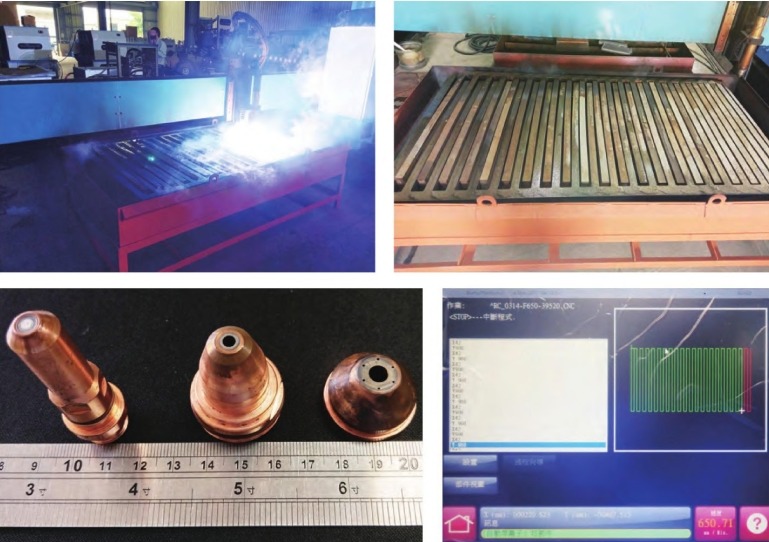

Testing Condition:

- Cutting Current: 800A

- Cutting Voltage: 180Vdc

- Thickness: 50mm

- Material: Stainless Steel

- Plasma Gas: Nitrogen

- Shield Gas: Pure Water (H2O)

- Cutting Speed: 650mm/min (Standard Speed: 830mm/min)

- Continuous Cutting Time: 1 hour (Consumables are in good condition

|

Item |

AVC-200 |

|

Motor Type |

Servo |

|

Operation Environment |

0~50℃, 95% relative humidity |

|

Control Accuracy |

±0.5VDC |

|

Max Speed |

80mm/sec |

|

Max Stroke |

275mm |

|

Lifting Capacity |

9.5kg |

|

Operation & Display |

4.7" Touch Panel |

These are our main advanced production processes to make the high-quality products for you.

Our products are all made in Taiwan from the beginning to the very end.

All the products have been tested and/or quality checked before delivery.

We are 100% confident about our product when it is delivered to the customer.

Professional management with qualified certificates & patents.

We inspect all parts during the packing process to ensure that our products are all in the best condition as designed.

PREV

PREV