Plastic Processing

The plastic objects form an integral part of our daily life. The manufacturing of all plastic solid objects involves use of plastic pellets which are heated to a high temperature in a chamber containing screw.

This heated & molten plastic is pushed through the chamber into the mould, where the molten plastic solidifies to become a plastic 3D object. During this process the screw gets worn out due to abrasion and heat related wear.

Taiwan Plasma Corporation contributes significantly to helping reduce wear with a very high-quality Plasma transferred Arc (PTA) coating. This coating is done using highly alloyed cobalt-based & other heat-resistant metal powders.

These powders are smoothly flown through the gas plasma arc, molten, and weld deposited.

The precise control of the current makes the dilution minimum. The dilution is just optimized to provide a very high-quality coating still retaining chemical properties to resist wear.

Typical Applications

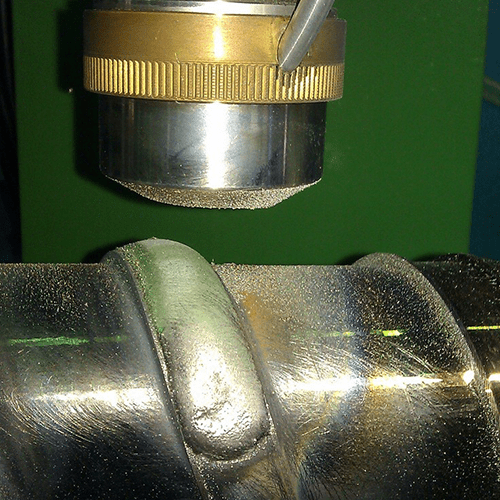

- Cladding of Screw flights with Plasma transferred Arc (PTA) coatings

- Cutting & Welding of the plastic processing machine(PPM) parts

Application Images