- Description

- Specification

- Additional Info

- Super-Cut Series PLASMA cutting machine provides Full PLASMA cutting functions to fit various metal cutting applications, including the following features:

• Water-Injection PLASMA Cutting: Narrow kerf, low deformation, less dust, and original color of cutting surface.

• Under-Water PLASMA Cutting: Minimize the deformation and cutting noise for stainless steel.

• Oxygen PLASMA Cutting: Deliver a high cutting speed and good cutting quality without nitrogenization problem in mild steel.

• Compressed-Air PLASMA Cutting: Supply gas charge for plasma cutting function.

• N2 PLASMA Cutting: Supply a low-cost and non-oxygenized PLASMA cutting for Stainless Steel.

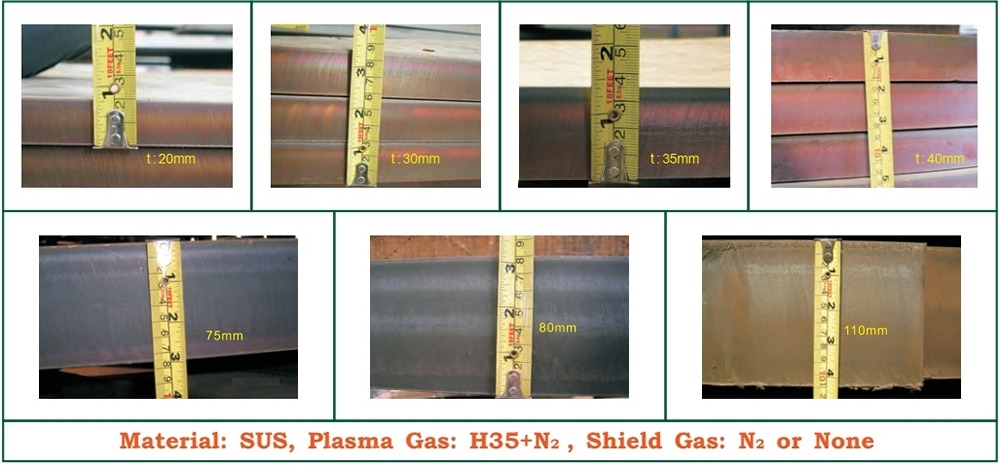

• H35+N2 PLASMA Cutting: Achieve a perfect cutting surface on stainless steel. - High duty cycle: 100% up to 4 Hours full power at loading. (@40℃).

- Higher cutting speed, which overtakes traditional cutting methods and laser cutting.

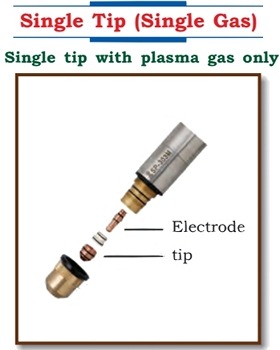

- Dual tip and single tip modes are available for selection:

• Dual tip: Provides much higher cutting speed, better capacity, and also the assistant tip can protect the spatter from the workpiece to extend the inner tip's life.

• Single tip: Less consumables, reduces the cutting cost - Compared to conventional PLASMA cutting, Flame cutting, and Laser Cutting machines, this equipment is able to deliver higher cutting speed and better productivity.

- Comes with a standard CNC interface, it's easy to connect to CNC, AVC, or a Robot to perform auto cut.

- Lower cutting cost:

• Oxygen long-life designed consumables, which reduces much running cost of spare parts.

• The number of consumables is reduced; it can only apply the electrode and tip in the single-tip model. - Powerful cutting capability:

• Cutting capability is up to 70mm in mild Steel (260Amp, Edge start) and 150mm in stainless steel (500Amp, Dry cut and edge start).

• Bevel cutting is available, cutting angle is up to 45°.

• Step adjusted current setting, the operator only needs to set up the parameter according to the cutting parameter to obtain a good cutting quality.

• Punch and PLASMA marking functions are available.

Full function of the Plasma cutting Machine. Simply press a button on the gas console, and the system will automatically select the suitable gases for mild steel or stainless steel. No gas modification is required when every time change the cutting material.

Remark:

- Customized specifications can be made upon request.

- Our products are manufactured according to the latest technology.

- We reserve all the rights for product improvement. Photo(s) are for reference only.

|

Item |

AVC-200 |

|

Motor Type |

Servo |

|

Operation Environment |

0~50℃, 95% relative humidity |

|

Control Accuracy |

±0.5VDC |

|

Max Speed |

80mm/sec |

|

Max Stroke |

275mm |

|

Lifting Capacity |

9.5kg |

|

Operation & Display |

4.7" Touch Panel |

These are our main advanced production processes to make the high-quality products for you.

Our products are all made in Taiwan from the beginning to the very end.

All the products have been tested and/or quality checked before delivery.

We are 100% confident about our product when it is delivered to the customer.

Professional management with qualified certificates & patents.

We inspect all parts during the packing process to ensure that our products are all in the best condition as designed.

PREV

PREV