- Description

- Specification

- Additional Info

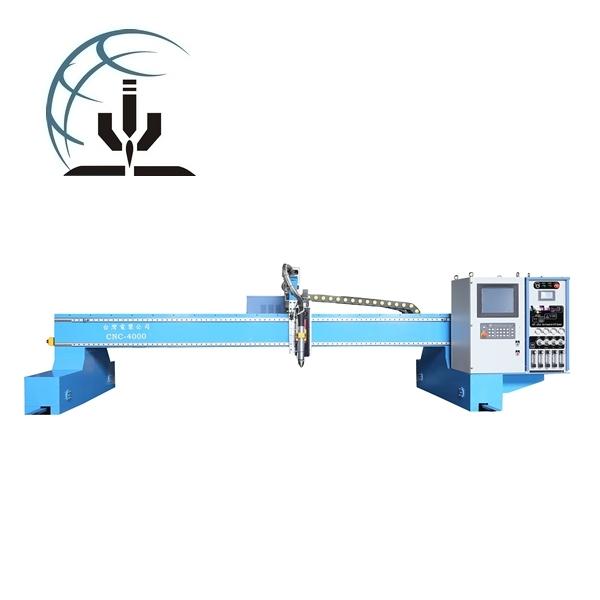

According to customer feedback and requests, we started to provide the entire cutting system to the customers. Not only the power supply and torch, but also the CNC system since 2007. Hereby, the complete system from one supplier, the customer will never experience the conflict between the power supply manufacturer and the CNC machine provider. Taiwan Plasma Corp. will be the one who provides the total solution for the client.

- CNC gantry is a dual-side servo motor drive designed, deliver high stability in high-speed motion.

- Drive servo motors are all applied Japanese high-accuracy model.

- Cross-direction drive: servo motor drive on grinding I-rail.

- The CNC gantry and cutting table are separately designed. This is to avoid the impact when hanging the plate on the table.

- To achieve high accuracy and long service period, the CNC gantry and rail are precision manufactured, hardened in the long and cross travel directions.

- Optional wireless control is available. The operator can control the machine's motion via a wireless device. (Conditions apply.)

- Cutting Capacity up to 200mm at Mil steel.

- Gas powder marking is available as an option.

- 6 flame torches are synchronizable for better productivity.

- Higher Productivity: 3~5 times higher cutting speed, no pre-heating is required to cut conductive material. Piercing can be done in 1 second. (Piercing capacity depends on the plasma power supply unit.)

- Better cutting quality: Reduce or even eliminate the second process after plasma cutting.

- Easier operation: Connect to a power gas supply and consumables everyone can achieve good cutting quality. No special expert is required.

- Safer environment: Can only apply compressed air for plasma cutting. No dangerous gas is involved.

- Lowest operation cost.

- Excellent cutting quality on non-ferrous material.

- Less deformation.

- Less heat-affected zone.

- Less metal dust.

- Dross-free cutting.

- Oxide-free cutting surface.

- Weld-ready cutting surface.

- Higher cutting speed and better cutting capacity. (Compared to underwater cut)

- No dust is generated during cutting.

- Extremely small heat-affected zone.

- Low cutting noise.

- Almost eliminate deformation.

- Weld-ready cutting surface.

- Best cutting quality (Cutting surface & verticality).

- Fastest cutting speed.

- Biggest cutting thickness.

Remark:

- Customized specifications can be made upon request.

- Our products are manufactured according to the latest technology. We reserve all the rights for product improvement.

- Photo(s) are for reference only.

These are our main advanced production processes to make the high-quanlity products for you.

Our products are all made in Taiwan from the beginning to the very end.

All the products have been tested and quality checked before delivery.

We are 100% confident about our product when it is delivered to the customer.

Professional management with qualified certificates and patents.