SS Powder for Sintered Filter

The powder with high porosity, stable chemical composition, and precise size distribution, which is the best choice for Stainless Steel 316L sintered filter—excellent corrosion resistance, heat tolerance, and compressive strength—and can be sintered into custom shapes for filters, silencers, and fire extinguisher components, addressing a broad range of industrial applications.

- Description

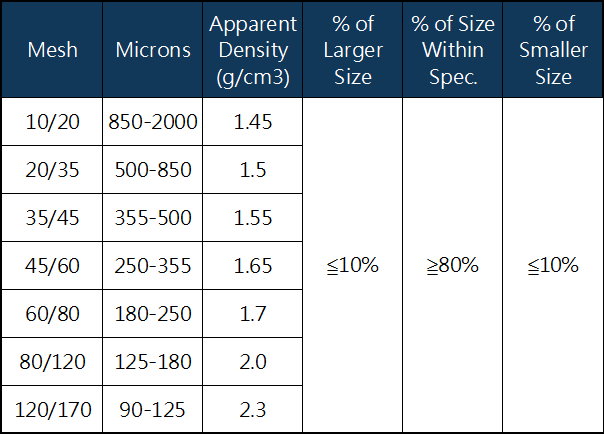

- Specification

- Additional Info

Our stainless steel filter powder is produced by water atomization. All of the raw material is strictly selected, and each of its weight percentages is precisely calculated when melted by an induction furnace. After melting, we will analyze the molten metal by arc-spark spectrometer to ensure the alloy composition complies with the specification. When pouring the metal out from the furnace into the tundish, the temperature of the metal is controlled within ±10℃. Then the metal will go through a well-designed atomizing die and be atomized into very irregular-shaped powder with high-pressure RO water in a N2 environment. After that, the powder will be collected, dewatered, dried, sieved, mixed, inspected, and then packed. Each of the processes is well operated and monitored, so our users are always using our high-quality and stable stainless steel filter powder.

TE-316L is a high Chromium-Nickel Alloy steel and which is very strong and good at corrosion resistance. As sintered filters require high porosity and high corrosion resistance, TE-316L powder with an irregular shape will be the most suitable choice to produce a high porosity filter by sintering after compacting into shapes as sheets, discs, or cylinders. In order to meet various filtration precision requirements, we have various particle sizes of filter powder for your selection.

If other size is required, please contact us.

These are our main advanced production processes to make high-quality products for you. Our products are all made in Taiwan from the beginning to the very end.

All the products have been tested before delivery. We are 100% confident about our product quality when it is delivered to the customer.

Carefully packing to ensure that our products are all in the best condition and quality.

PREV

PREV