Plasma Heating Machine

The plasma heating system not only provides a higher temperature environment, but is also faster to achieve high temperatures, able to use different gases to achieve different temperatures and effects on the result, and can directly disintegrate matter in an oxygen-starved environment.

- Description

- Specification

- Additional Info

Plasma is the fourth state of matter beyond solid, liquid, and gas, composed of positive ions, electrons, atoms, and molecules. The center temperature of plasma flame can reach 5,000 ~ 10,000℃ or even higher, producing an operating environment above 2,000℃ (depending on furnace materials) along with strong ultraviolet radiation.

Compared with traditional combustion heating systems on the market, this plasma heating system not only produces higher temperatures but also offers the following advantages:

- Ultra-high thermal transfer efficiency enables reaction rates in the high-temperature reaction zone to exceed combustion chambers by more than ten times.

- Different chemical properties of dissociated gases allow for various reaction temperatures and effects.

- The plasma gasification process results in minimal energy loss, maximizing energy utilization.

- Electric heating control enhances safety and system controllability.

- Materials can be directly pyrolyzed in low-oxygen or oxygen-free environments.

- Plasma flames contain abundant UV light that accelerates chemical reactions.

- Constant-current control with DC output.

- Temperature-feedback and fully enclosed control loop maintain stable furnace temperature.

- Capable of 24-hour full-load continuous operation for over one month.

- Switch-mode power supply delivers stable output with ripple ≤10% and power factor ≥90%.

- IGBT chopper design ensures highly stable current output.

- Touchscreen operation panel.

- Highly customizable: power rating, chopper/inverter/SCR options available.

-Nitrogen-powered extreme temperatures for safe, low-carbon, and high-efficiency heating

Features:

- Economical & Efficient: Uses stable and easily accessible nitrogen.

- High Performance: Generates high temperature in atmospheric or oxygen-free environments.

- Eco-safe: No fuel combustion and low carbon emissions.

- Future Expandable: Modular design enables flexible upgrades.

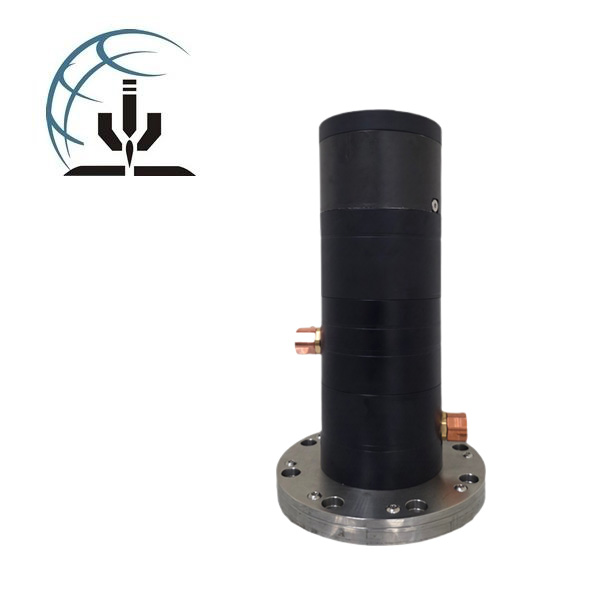

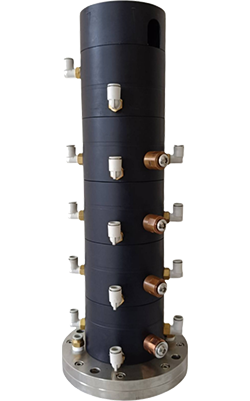

PH-T23

PH-T33

PH-T43

PH-T53

- Metallurgy and material smelting

- Waste treatment and environmental protection

- Powder metallurgy and new material preparation

- Surface engineering

- Chemical synthesis and other industrial applications

| Model | PH2-15T | PH3-25T | PH4-35T | PH5-50T | PHS-100 | PHS-400 | PHS-1000 |

|---|---|---|---|---|---|---|---|

| Max Current | 80A | 75A | 90A | 100A | 200A | 500A | 1250A |

| Max Voltage | 200V | 350V | 400V | 500V | 500V | 800V | 800V |

| Max Power | 15kW | 25kW | 35kW | 50kW | 100kW | 400kW | 1000kW |

| Torch | PH-T23 | PH-T33 | PH-T43 | PH-T53 | |||

Notes:

- Other power voltages or special specifications are accepted for custom orders.

- The product is under continuous development. Taiwan Plasma Company reserves the right to modify machine specifications without prior notice.

- Product photos are for reference only.

These are our main advanced production processes to make high-quality products for you.

Our products are all made in Taiwan from the beginning to the very end.

All the products have been tested and/or quality checked before delivery.

We are 100% confident about our product when it is delivered to the customer.

Professional management with qualified certificates & patents.