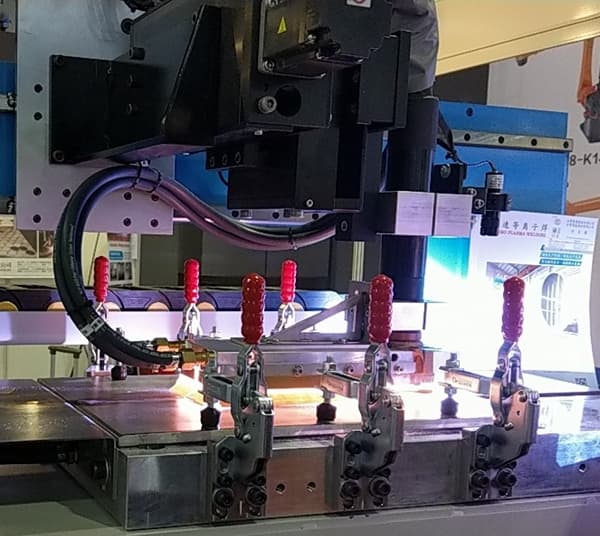

800A Turbo TIG Welding Machine

Extremely high speed welding. When welding a stainless steel plate with 10mm thickness, no bevel cut is needed in advanced and the welding speed could be as high as 450mm/min, which is more than double that of a traditional plasma welder.

- Description

- Specification

- Additional Info

- Improving the productivity & quality

- Shortening process & reducing cost

- Simplifying the welding operation

- This is a new-tech welding machine, which doesn’t require very skilled personnel to operate. After a few hours of training, a normal welder can easily make a great welding job with the machine.

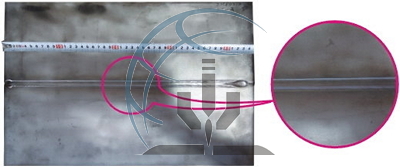

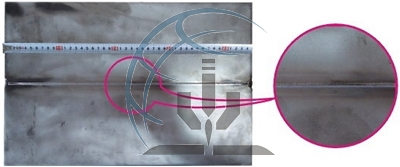

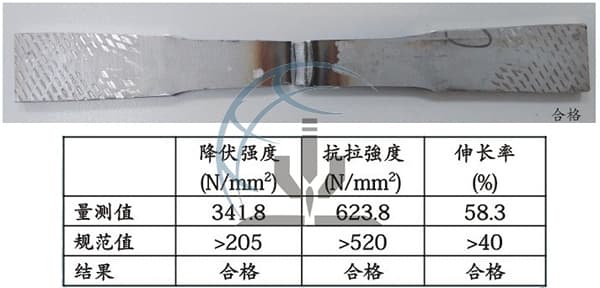

- Excellent and stable quality with a very high welding speed. The welding speed can be as high as 600mm/min for 8mm thickness, 450mm/min for 10mm thickness, and 300mm/min for 12mm thickness of Stainless Steel.

- Simplifying the welding procedure. No edge planning, grooving, and back gouging is needed before and after welding, which can eliminate a lot of working hours, energy, and cost of material.

- Due to the dramatically increased speed, heat input is greatly reduced, which also results in less working time on the workpiece.

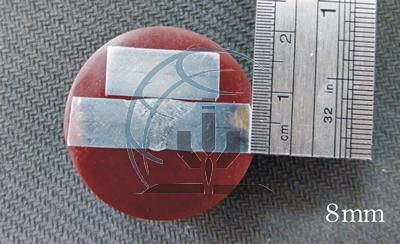

- Stainless steel ≤ 14mm of thickness can be welded without grooving in advance, so operators can reduce or even eliminate the amount of wire.

6mm>900mm/min

8mm>600mm/min

10mm>450mm/min

12mm>300mm/min

14mm>150mm/min

Speed of SS304 Welding (Square butt joint)

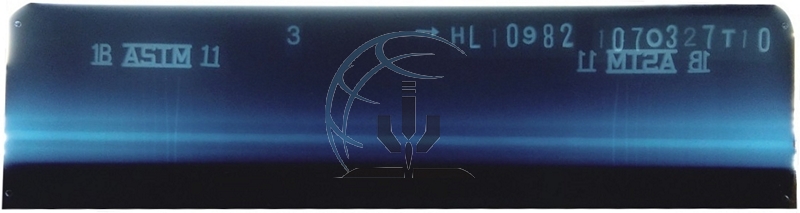

Frontview of weiding bead

Backview of welding bead

Remark:

- Customized specifications can be made upon request.

- Our products are manufactured according to the latest technology.

We reserve all the rights for product improvement. - Photo(s) are for reference only.

These are our main advanced production processes to make high-quality products for you. Our products are all made in Taiwan from the beginning to the very end.

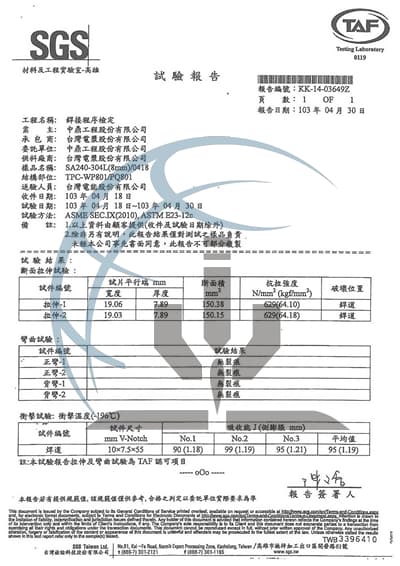

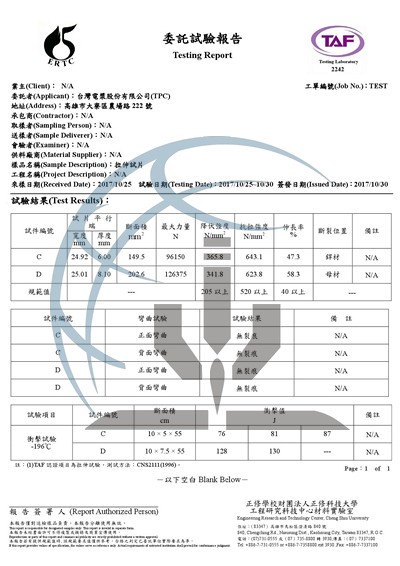

All the products have been tested and/or quality checked before delivery. We are 100% confident about our product when it is delivered to the customer.

Professional management with qualified certificates & patents.

We inspect all parts during the packing process to ensure that our products are all in the best condition as designed.